Proceedings

Three paths to the perfect surface

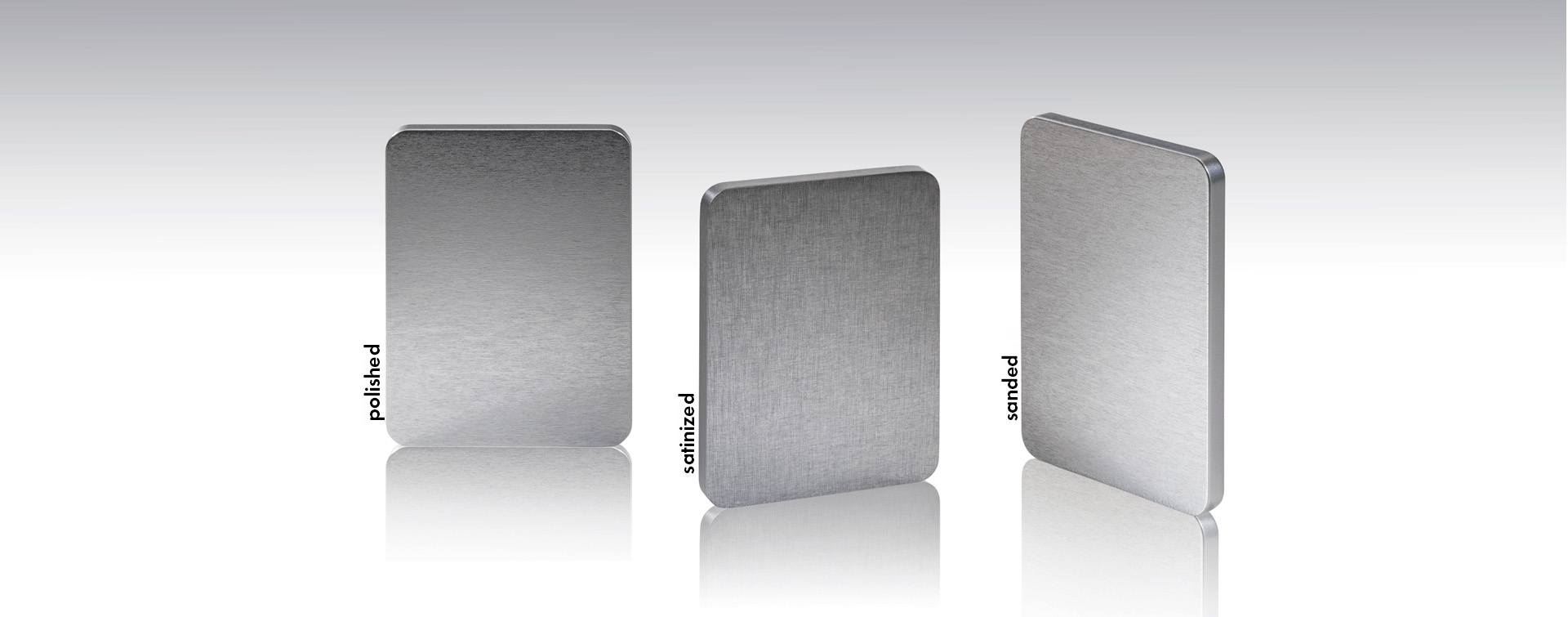

To achieve a perfect surface, Aurolia primarily utilizes three electroplating processes. With their assistance, we can positively influence many important properties of the material. Aurolia surfaces are harder, more durable, more wear-resistant, and corrosion-resistant. Our customers specify the requirements, and we create a surface layer that precisely meets their needs, from functionality to texture and appearance.

Overview of our processes

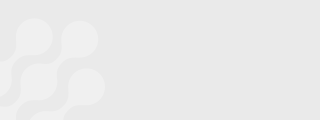

Anodized black

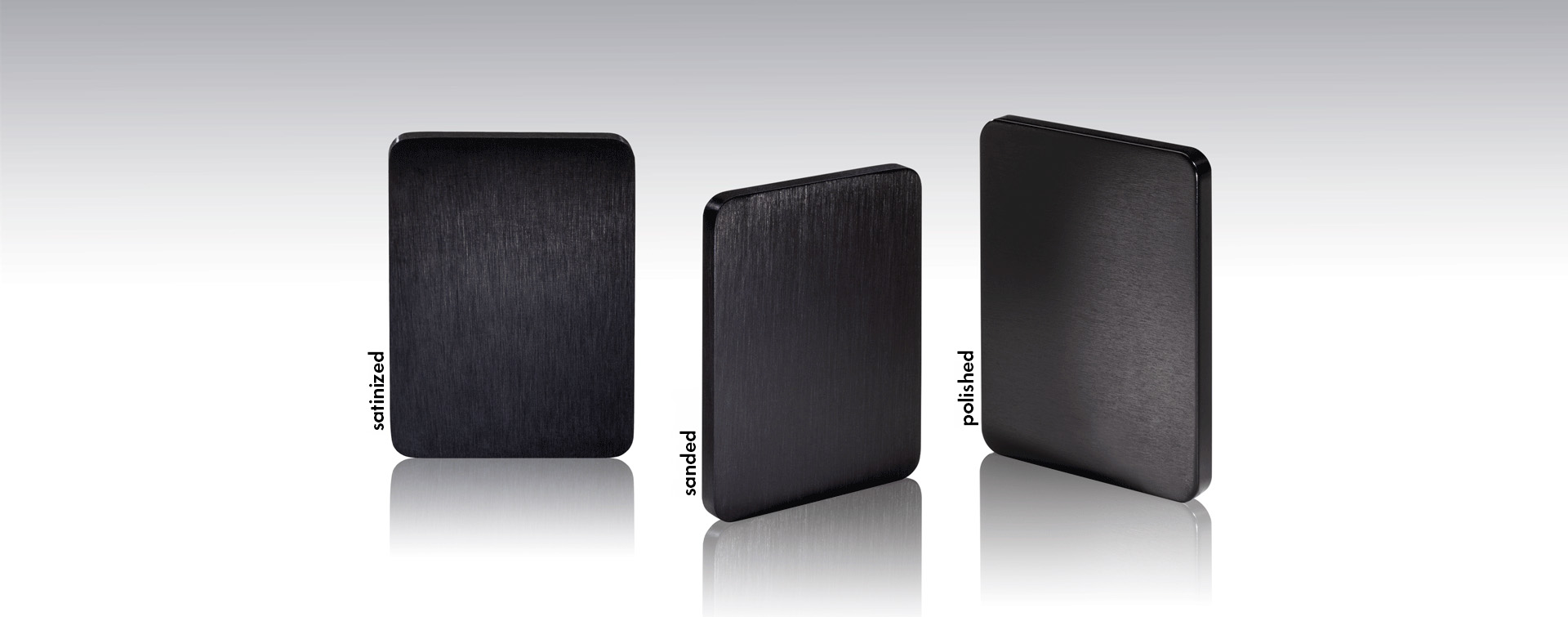

Anodized natural matte etching

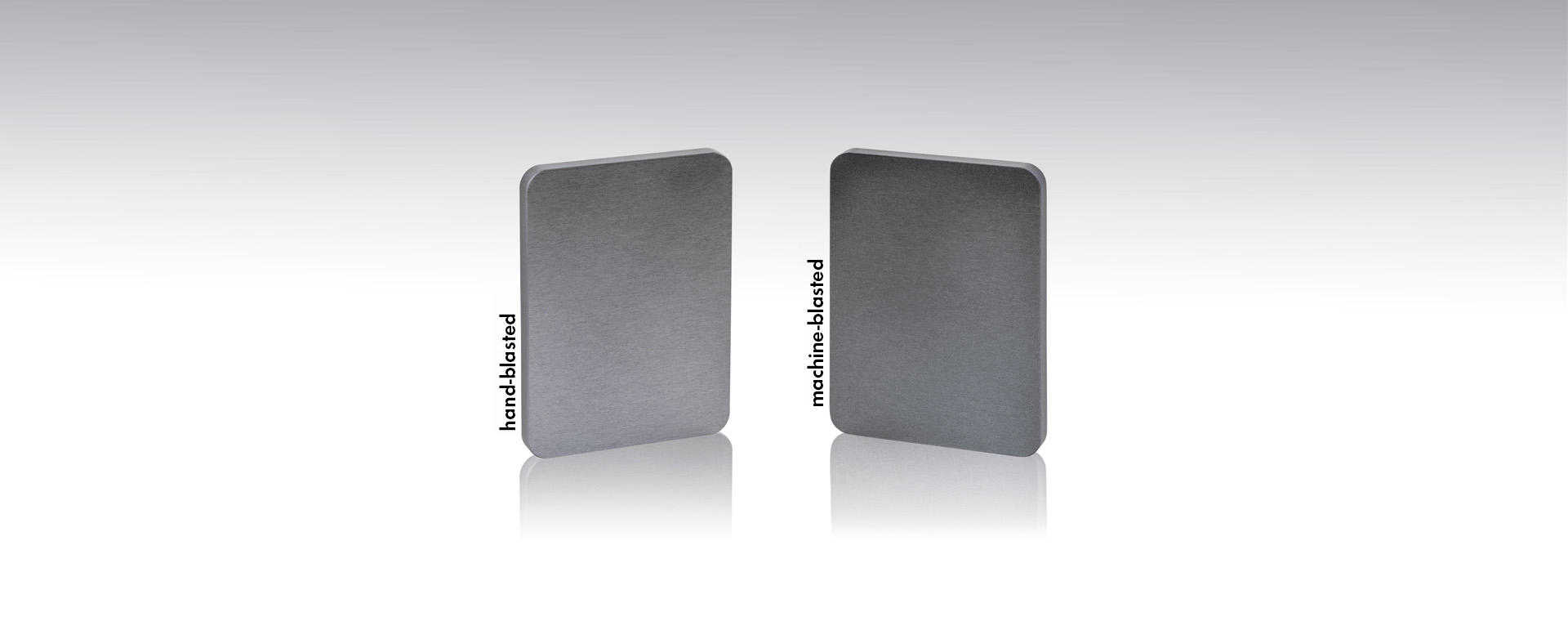

Anodized black decorative etching

Anodized natural

Anodizing

Description

Anodizing provides aluminum with an oxide layer, protecting it from corrosion. This process also occurs naturally, but we manipulate it intentionally to achieve various beneficial properties. We create a layer thousands of times thicker than in nature, three times as hard, with a luxurious texture and appearance. Whether high-gloss, matte, low reflection, stainless steel appearance, or targeted concealment of surface defects, through various processing steps, we enable a wide range of appearances and colors. And thanks to the PLC control of our coating system, we can quickly and accurately reproduce any surface result.

Hard facts

We offer you the following advantages in a work window of 1200 x 700 x 300 mm:

- Decorative mechanical pretreatment

- Tailored coating processes

- Etching as desired

- Coating thicknesses from 5-25 µm

- Coloring according to your preferences

- Good corrosion protection

- Two-stage sealing process

- Good hardness of approximately 200 HV

We are happy to conduct a sampling.

Innovative Anodizing Techniques for the Highest Demands

Anodizing, also known as electrolytic oxidation (Eloxal), is a crucial process that makes aluminum surfaces durable and long-lasting. Particularly when applying black anodizing, not only is excellent corrosion protection ensured, but also an aesthetically pleasing surface that is simultaneously highly functional. This technique is ideal for projects where design and durability are equally important.

Our company offers customized solutions in the field of anodizing, ranging from glossy surfaces to matte and low-reflection variants, and even unique stainless steel looks. Thanks to cutting-edge technology and precise PLC control, we guarantee consistent results and top-quality finishes.

Our black anodized surfaces are especially popular as they offer a luxurious, deep black color that is both robust and scratch-resistant.

For demanding applications, we offer coating thicknesses from 5-25 µm, which can be selected according to specific needs and requirements. The additional ability to dye aluminum surfaces in various colors allows us to meet individual customer desires with precision.

Discover the versatile applications and outstanding benefits of anodizing and let our expertise convince you.