Proceedings

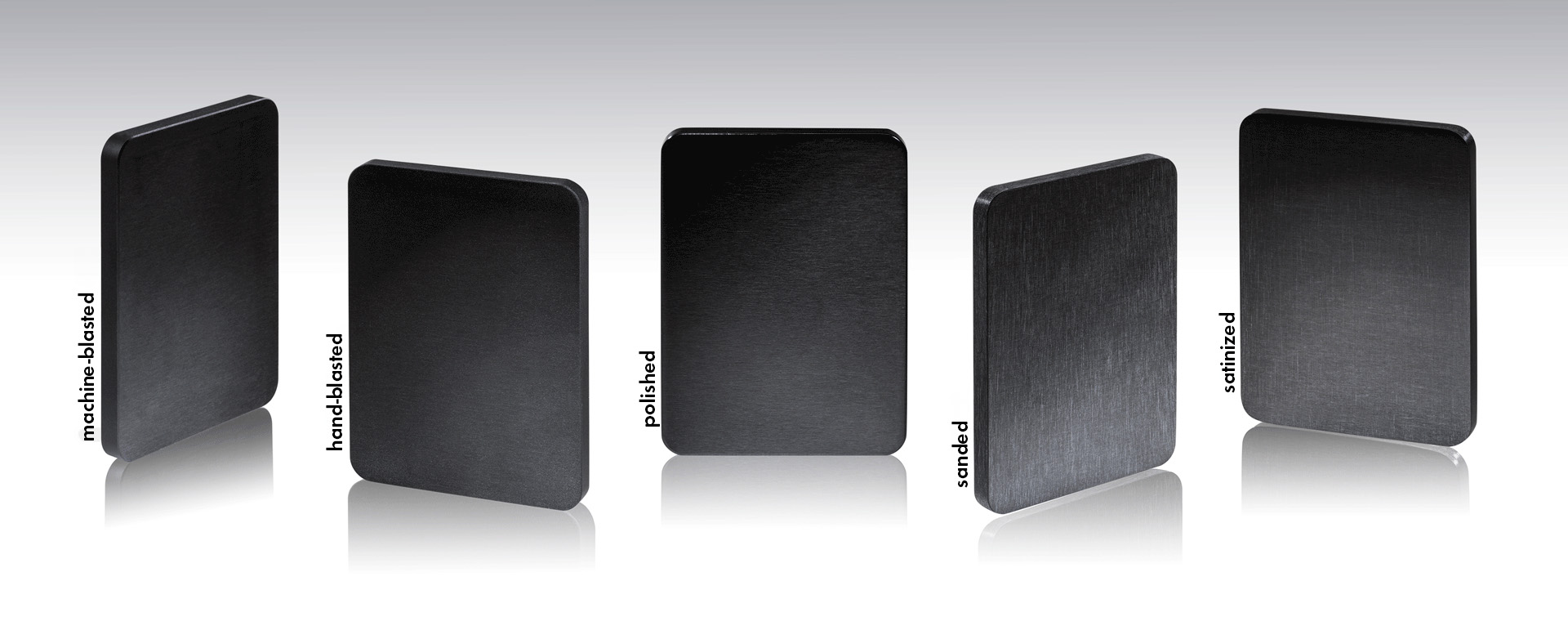

Three paths to the perfect surface

To achieve a perfect surface, Aurolia primarily utilizes three electroplating processes. With their assistance, we can positively influence many important properties of the material. Aurolia surfaces are harder, more durable, more wear-resistant, and corrosion-resistant. Our customers specify the requirements, and we create a surface layer that precisely meets their needs, from functionality to texture and appearance.

Overview of our processes

Hard anodizing

Description

In hard anodizing, aluminum materials are immersed in a special bath. By applying electrical current, targeted oxidation on the surface is provoked, giving the material extremely valuable properties. For instance, hard anodized aluminum is particularly resistant to wear, electrically insulating, and offers excellent corrosion protection. Having a component hard anodized at Aurolia means being able to determine many properties of the material itself. Hard anodized layers can range in color from light gray to gold to brown, but can also be dyed black. Additionally, to improve sliding properties, we can apply a PTFE coating, which gives the surface a lotus-like cleaning effect.

Hard facts

In our fully automated finishing plant, with a work window of 1200 x 700 x 300 mm, we can offer the following properties of hard-anodized oxide layers:

- Coating thicknesses from 25 to 100 µm

- Minimal variance in coating thickness distribution

- Excellent corrosion protection

- High wear resistance

- Hardness of approximately 500 HV (depending on the alloy)

- Food-safe

- Decorative appearance

- Excellent sliding properties due to PTFE incorporation

- Black coloring

We are happy to conduct a sampling.