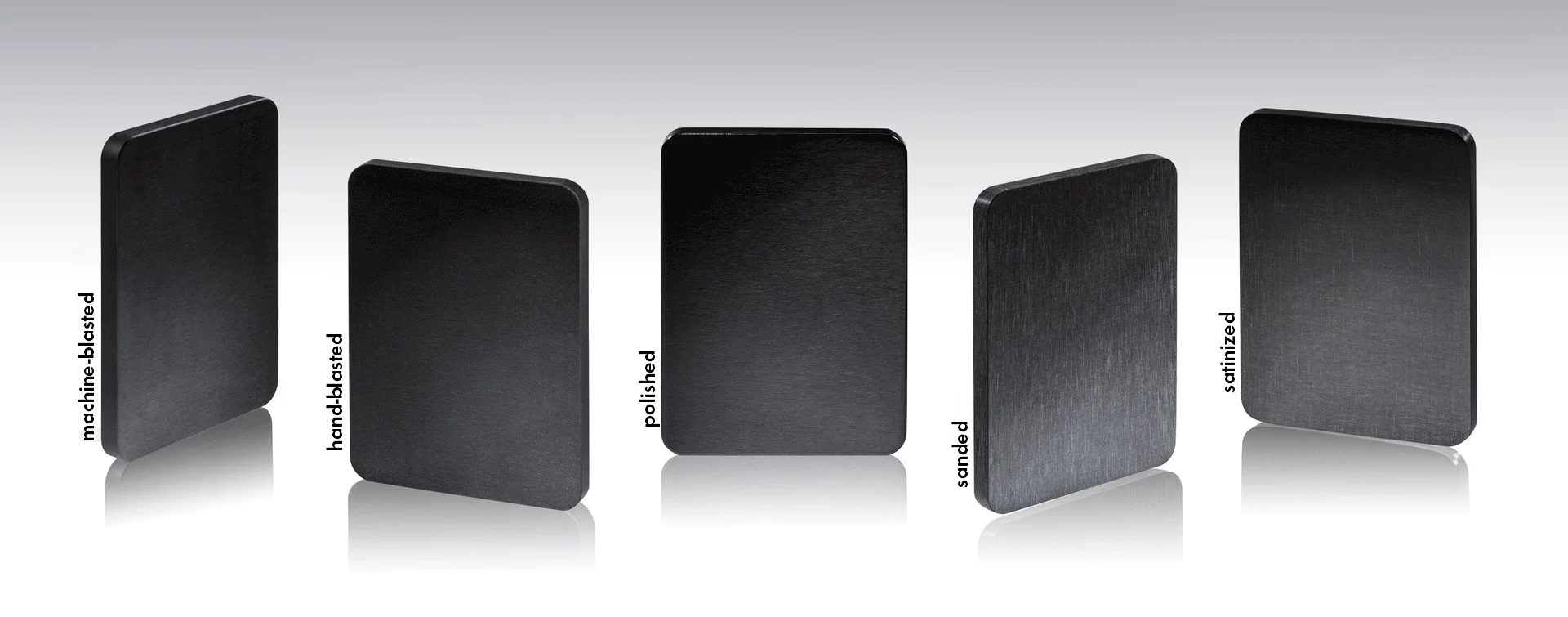

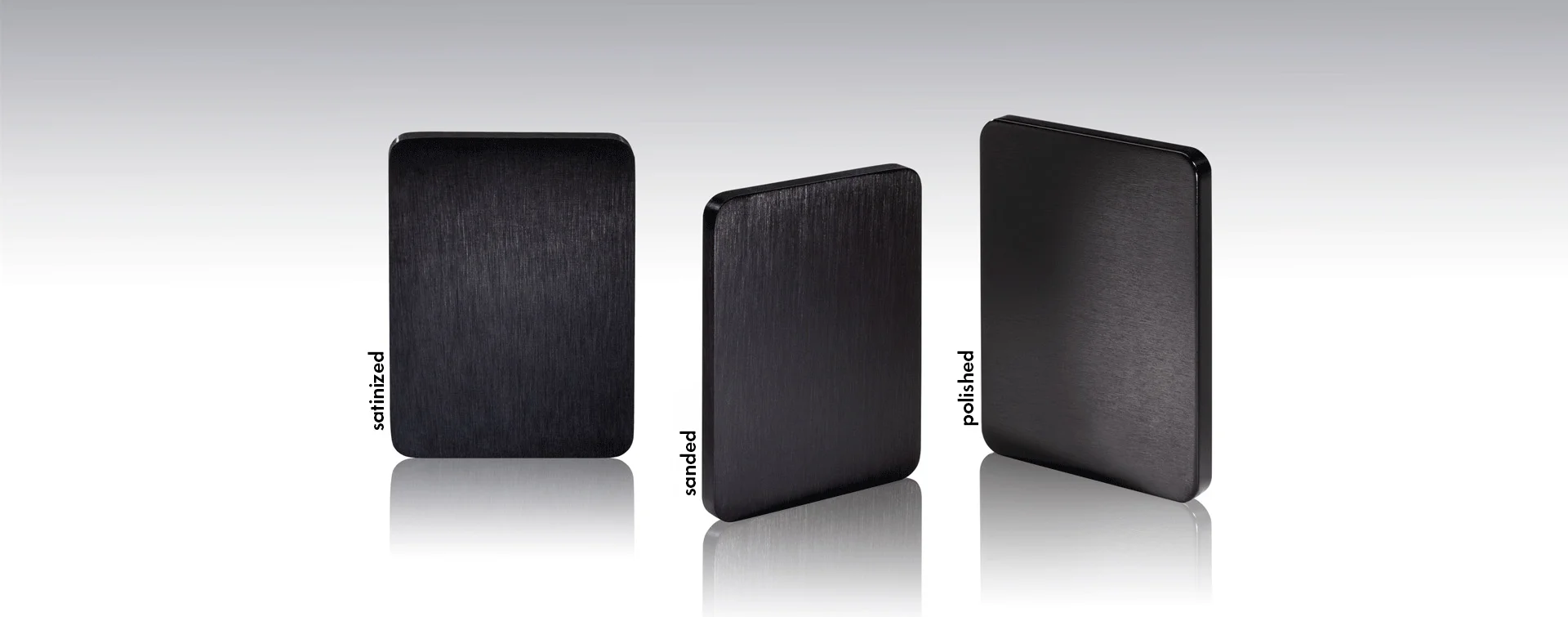

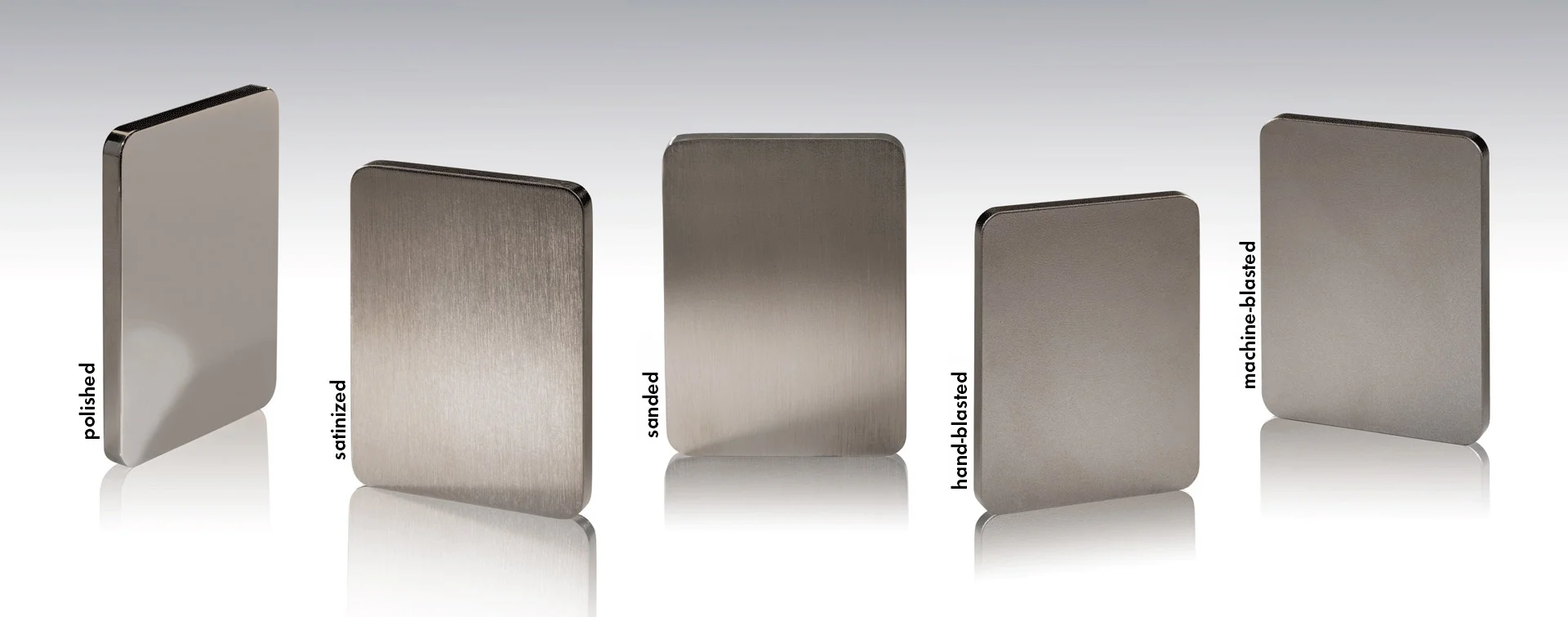

Surface finishing in comparison

Anodizing, electroplating, hard anodizing, or electroless nickel plating – which process is right for your component?

In industrial surface technology, there is no one-size-fits-all process – only the optimal solution for each specific application. Whether it’s corrosion protection, increased hardness, or decorative finishing: At Aurolia Technologies, we offer a range of precise processes for aluminum and metal treatment – and provide expert, application-specific advice.

An overview of the most important processes

Hard anodizing

High-strength protective coatings with excellent hardness – ideal for heavily stressed components.

Typical applications:

- Hydraulic components

- Pistons & guides

- Mechanical engineering

Key advantages:

- Coating thicknesses 25 — 100 µm

- Excellent wear and corrosion resistance

- Good electrical insulation

Anodizing (Electrolytic Oxidation)

Typical applications:

- Design housings

- Medical technology

- Electronic components

Key advantages:

- Thin coating (typically 5–25 μm)

- Good hardness of approximately 200 HV

- Preserves the material’s color and texture

- Electrically insulating and corrosion-resistant

Electroless Nickel Plating (EN Plating)

Typical applications:

- Toolmaking

- Injection molds

- Precision parts

Key advantages:

- Absolutely uniform coating distribution

- Hardness up to approx. 1000 HV after heat treatment

- Tight tolerances of ±2 μm

- Excellent resistance to corrosion and chemicals

- RoHS, ELV, and FDA compliant

Additional Finishing Processes

We also offer additional processes for technical or decorative finishing.

Examples:

- Passivation

- Polishing

- Glass bead blasting

- Screen printing / laser marking

- PTFE

Comparison Table: Overview of the Processes

Process

Materials

Coating Thickness

Special Feature

Typical Applications

Hard Anodizing

Aluminium

25 — 100 µm

Extreme Hardness

& Insulation

Mechanical Engineering, Hydraulics

Anodizing

Aluminium

5–25 µm

Decorative &

Corrosion-Resistant

Design, Electronics

Electroless Nickel Plating

Steel, Brass

5–25 µm

Uniform Nickel Coating

Tools, Mold Making

Additional Processes

Aluminium, Metal

–

Custom Finishing Touch

Tailor-Made

Which process is right for your product?

Unsere Spezialisten beraten Sie kompetent und finden gemeinsam mit Ihnen die beste Lösung – abgestimmt auf Material, Anwendung und Einsatzumgebung.

FAQ – Surface Technology

Which factors influence the coating thickness in hard anodizing?

The achievable coating thickness depends on factors such as the alloy composition of the aluminum, the current density, the bath temperature, and the treatment duration. In particular, highly alloyed materials require an adjustment of process parameters to ensure optimal results.

How does dimensional accuracy change with electroless nickel plating?

Electroless nickel plating allows for a very uniform coating thickness distribution – even on complex geometries. The dimensional change typically corresponds to half the coating thickness (as the layer forms both inside and outside), but it is highly predictable and easy to calculate.

Which aluminum alloys are problematic for anodizing?

Alloys with a high copper, silicon, or zinc content tend to result in uneven layer formation, color variations, and reduced adhesion. Good results can be achieved with alloys such as AlMgSi0.5 (6060) or AlMg3 (5754).

How can the hardness of a hard anodized layer be specifically controlled?

Hardness can be influenced by precise process control (temperature, voltage, electrolyte composition) and post-treatments such as calcination or sealing. Typical values range from 350–500 HV, but special processes can achieve up to 600 HV.

When is electroplated nickel inferior to electroless nickel?

Electroplated nickel tends to produce irregularities at edges and recesses. In contrast, electroless nickel provides a uniform coating thickness but is more material- and cost-intensive. For precision components with complex geometries, electroless nickel offers clear advantages.

What role does coating porosity play in anodizing?

The natural porosity of the anodized layer is crucial for the absorption of dyes and for the adhesion of subsequent layers (e.g., paints). To achieve maximum corrosion resistance, thorough sealing (e.g., with hot water or nickel salt solutions) is essential.

What about the dielectric strength of anodized layers?

Anodic oxide layers offer good insulation properties. Dielectric strength depends on the coating thickness, alloy type, and sealing. Typical values range between 500 and 2000 V/μm.

Which pre-treatments are mandatory before hard anodizing?

Thorough degreasing, chemical etching, and, if necessary, desmutting are essential to ensure homogeneous layer formation. In particular, alloy residues or mill scale must be removed.

How do hard anodized coatings differ from thermal hard coatings?

Hard anodized coatings are formed electrochemically and are an integral part of the substrate, whereas thermal coatings (e.g., PVD, CVD) are applied onto the surface. Hard anodizing offers particularly high adhesion, while thermal coatings provide greater diversity in composition.

Are there electroplating processes for aluminum?

Yes – however, aluminum must be chemically pretreated and activated (e.g., with zincate) before electroplating. After this, metals such as nickel, copper, or gold can be electroplated. The process is more complex than with steel or brass.