Aurolia – the New Facility

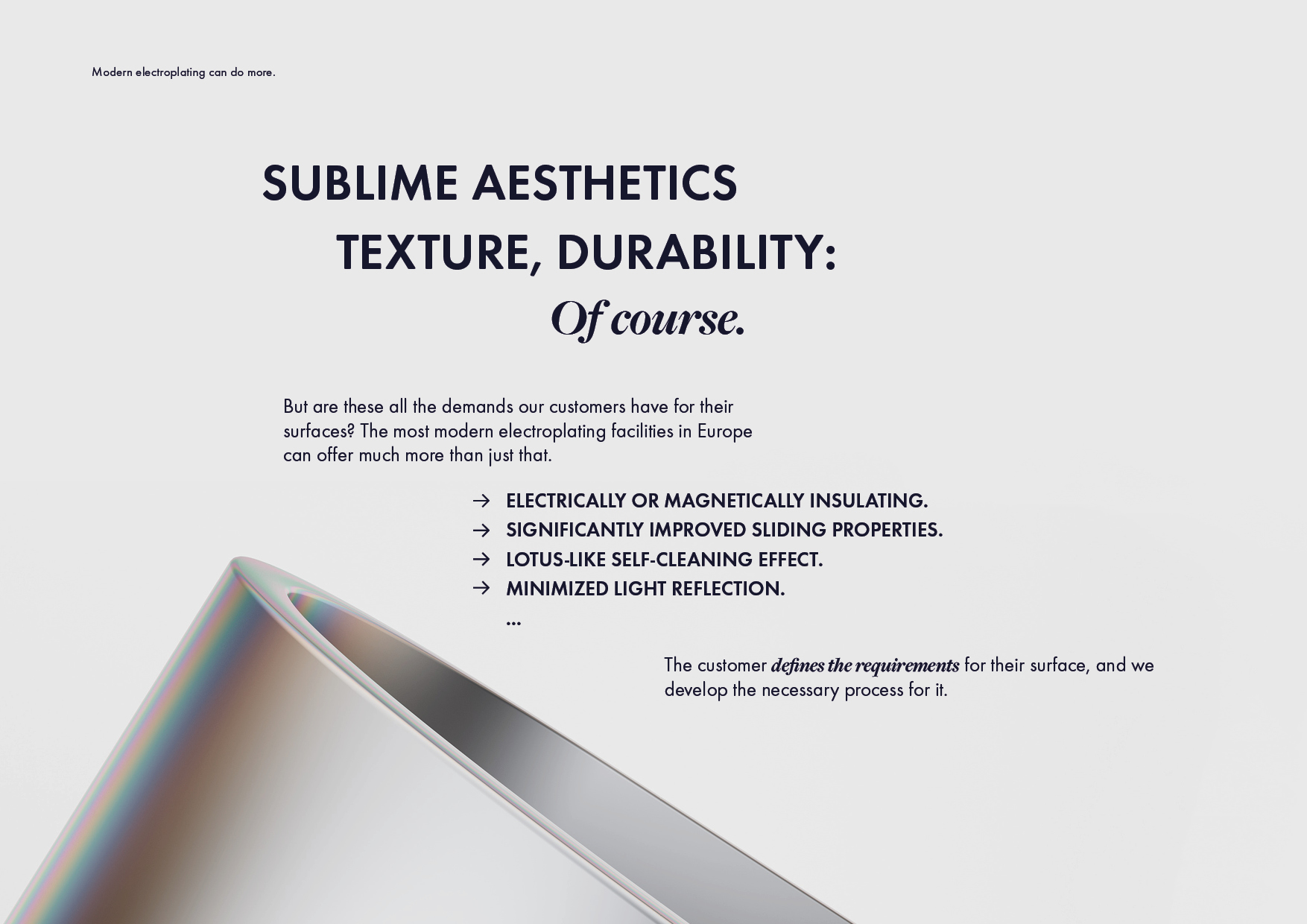

Imagine a world without friction and wear.

Are you ready for Galvanization 4.0?

THIS VISION

DRIVES US!

It drives us to continuously develop our processes and push the boundaries of what is possible with electroplating.

Always at the forefront are the immediate challenges of our customers. Solving your problems drives the evolution of our services. Keeping abreast of industry developments, with innovative approaches from surface technology for the success of your products.

YOUR CHALLENGES

DRIVE US FORWARD.

OUR SOLUTIONS ARE YOUR COMPETITIVE ADVANTAGE.

CO2-NEUTRAL

Clear corporate ethics promote and demand sustainable interaction with humans and the environment, including certified CO2 neutrality.

AUTOMATED.

Assembly, coating, quality control, packaging, and documentation are done completely automatically.

DIGITIZED.

AI-driven production planning system,

Customer portal with CAD-based order configurator and comprehensive product tracking.

EFFICIENT.

State-of-the-art robotics maximize process productivity and minimize resource and energy consumption per coated part.

The new on-site environmental technology features state-of-the-art wastewater and fresh water treatment. This allows raw materials to be returned to the cycle and reused. Thanks to ergonomic workplace design and the 3-in-2 shift system, the new plant enables a quantum leap in terms of employee sustainability. A sixfold increase in productivity, combined with significantly improved working conditions and complete carbon neutrality: We’ve got it.

Newsticker

September 12, 2024

Digital factory tour

The year 2025 promises to be a groundbreaking development in the electroplating industry with the brand-new plating plant currently under construction.

26th of September 2023

Approval process is underway

Aurolia plans to establish permit-required facilities according to the Federal Immission Control Act (BImSchG) at the new location in ITT Thüringer Tor.

3rd of September 2023

Energy concept close to completion

“Dependence on CO2 neutrality energy concept is nearing completion.”

The transformation of Germany into a carbon-neutral industrial nation is a central structural challenge of our time.

30 th of August 2023

Archaeological report

“Archaeological assessment successfully completed” – As our construction site is located in an archaeologically significant area, as a resident company of the Free State of Thuringia, we are obligated to undergo an archaeological assessment.

UNIQUE WORLDWIDE,

FULLY AUTOMATED ANODIZING PLANT

Enhances over 200 different aluminum alloys

From highly decorative to highly technical

Goods window of 2,400×1,200 mm

Goods capacity of up to 5.8 m² per carrier

Layer thickness up to 200 μm

Hardness of up to 1,000 HV

WHAT ELSE WE CAN DO

Passivating

Mechanical surface finishing

Laser marking

Prototype and initial sample processing

Development and construction of custom material carriers

HIGHLY FLEXIBLE

CHEMICAL NICKEL PLANT

Various final coatings (tin, gold, silver) feasible

Many additional product properties possible

Goods window of 1,200×800 mm

Goods capacity of up to 1.9 m² per goods carrier

Close tolerances of +/- 2 μm

WHICH MATERIALS WE ENHANCE

Aluminum

Steel

Stainless steel

Gray cast iron

Non-ferrous metals

SECURE CAPACITIES

AND BE PART OF IT AT THE START OF THE FIRST QUARTER OF 2025!

CURRENTLY, SAMPLING IS TAKING PLACE.