References

Aurolia Success Stories

Aurolia Success Stories

Aurolia Technologies GmbH has been awarded the TOP 100 Seal 2025, officially ranking among the most innovative medium-sized companies in Germany.

This award sends a strong message – to our customers, our partners, and the industrial region of Thuringia. It recognizes our consistent work on innovative solutions in surface technology and affirms the path we have followed as a team for years with conviction: technologically leading, sustainably focused, and collaboratively connected.

We are particularly proud that our innovative strength has now been recognized not only on stage, but also on television: The German broadcaster MDR has dedicated a company profile to Aurolia. The feature offers personal insights into our way of thinking, presents real-world examples, and introduces the people behind our vision: a world without friction and wear. [more…]

A customer requested 480 hours of resistance in the salt spray test for EN AW 7075 with a 30 µm hard anodized coating—a significant challenge for this material. At that time, we narrowly missed the mark, but this motivated us to further improve.

The result: An impressive 2016 hours of resistance according to DIN EN ISO 9227. This progress underscores our commitment to durable, innovative solutions.

Our Facts:

- Material: EN AW 7075

- Coating: 30 µm, tested using eddy current measurement

- Result: 2016 hours of resistance

We stand for the highest corrosion protection standards—let’s work together to meet your requirements!

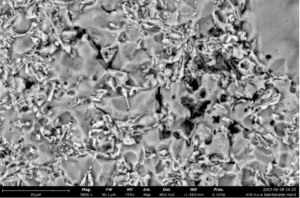

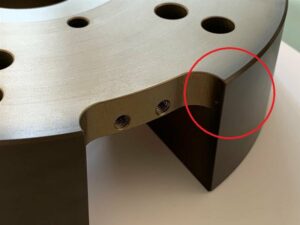

AC 46000: A Masterpiece in Surface Technology.

Das Aurolia-Team hat sich mittlerweile einen Ruf dafür erarbeitet, die Herausforderungen ihrer Kunden als spannende Gelegenheiten anzusehen, und dieser Fall war keine Ausnahme. hierbei ging es nicht einfach nur darum, ein gewünschtes Bauteil aus AC 46000 in dekorativer und ansprechender Form herzustellen.

Das Aurolia-Team hat sich mittlerweile einen Ruf dafür erarbeitet, die Herausforderungen ihrer Kunden als spannende Gelegenheiten anzusehen, und dieser Fall war keine Ausnahme. hierbei ging es nicht einfach nur darum, ein gewünschtes Bauteil aus AC 46000 in dekorativer und ansprechender Form herzustellen.

The Aurolia team has earned a reputation for viewing their clients’ challenges as exciting opportunities, and this case was no exception. It wasn’t just about producing a component from AC 46000 in a decorative and appealing form. Rather, our goal was to achieve a very specific property, one associated with exceptionally high adhesive strength.

Process optimization eliminates the need for hydrofluoric acid.

Impossibly Refined

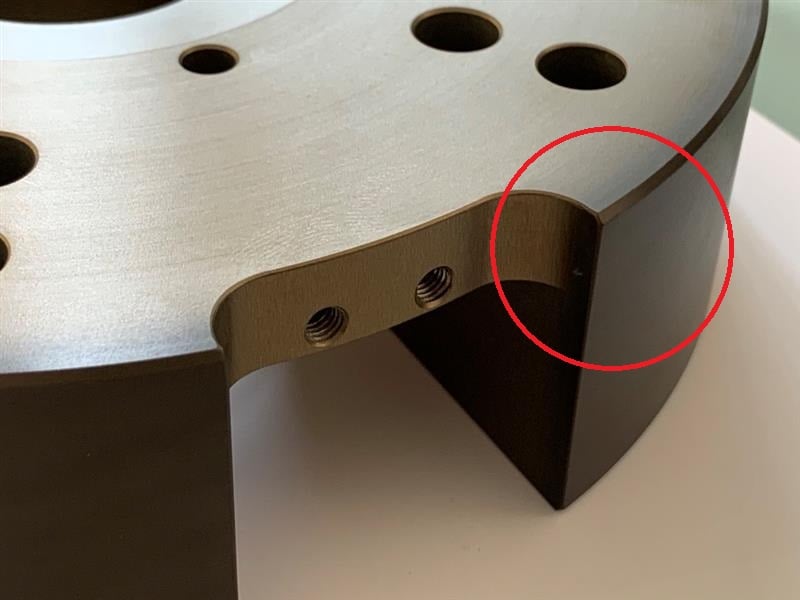

A client approached us with the request to coat the alloy AW 7075 T6511—after several plating companies had already declined, stating it wasn’t possible. The alloy, stretched in the T6511 condition, has hardened edge areas that show up as a dark fringe after coating. Hardness testing of the material revealed a difference of over 50 Brinell between the edge and the core, with percentage losses increasing as the diameter of the component grows. Our solution: If manufacturers apply a small machining allowance to the workpiece and remove the hardened edge, the alloy AW 7075 in the T6511 condition—previously considered unsuitable for coating—can be refined to a high standard with a uniform finish.

A client approached us with the request to coat the alloy AW 7075 T6511—after several plating companies had already declined, stating it wasn’t possible. The alloy, stretched in the T6511 condition, has hardened edge areas that show up as a dark fringe after coating. Hardness testing of the material revealed a difference of over 50 Brinell between the edge and the core, with percentage losses increasing as the diameter of the component grows. Our solution: If manufacturers apply a small machining allowance to the workpiece and remove the hardened edge, the alloy AW 7075 in the T6511 condition—previously considered unsuitable for coating—can be refined to a high standard with a uniform finish.